Following our recent visit to St. John the Devine Church, we thought it might be interesting to research the history and use of No Fines Concrete in Coventry and elsewhere.

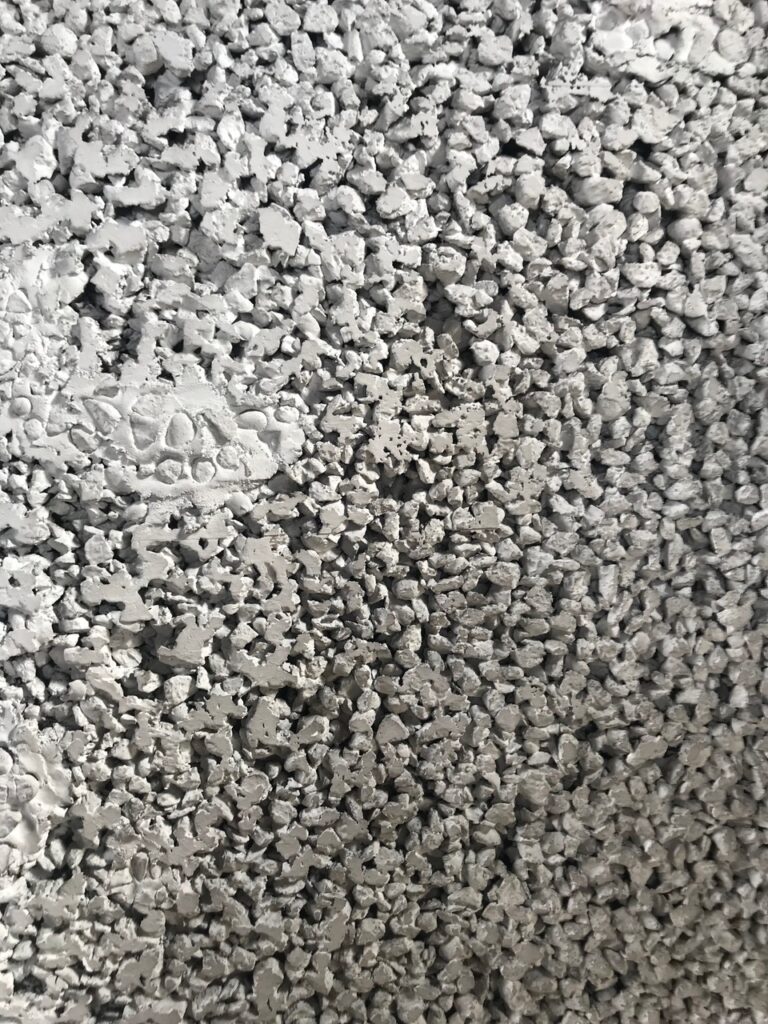

No-fines concrete is a form of lightweight concrete made without fine aggregates (such as sand), using only coarse aggregates, cement, and water. The result is a highly permeable, low-density material with a distinctive open texture.

In Coventry, no-fines concrete became particularly significant during the post-war reconstruction period. Following the devastation of the Blitz in 1940, Coventry faced an urgent need for rapid, cost-effective housing. Local authorities adopted no-fines concrete as part of large-scale housing schemes in the late 1940s and 1950s, often in partnership with the Scottish Special Housing Association, which pioneered the method.

The benefits for Coventry were twofold: speed and availability. The omission of fine aggregates reduced material costs and allowed for quick on-site construction using reusable formwork. The material’s insulating properties were also seen as advantageous for domestic housing. However, many of Coventry’s no-fines concrete homes later faced challenges, including poor thermal performance by modern standards, difficulties with damp ingress, and complications when retrofitting insulation or new finishes. Despite these drawbacks, the use of no-fines concrete in Coventry remains an important example of innovative post-war building methods. Today, many of these properties still stand and are part of the city’s architectural and social heritage.

George Wimpey & Co. (later Wimpey Construction) was one of the largest housebuilders in the UK after the Second World War and played a key role in popularising no-fines concrete for mass housing.

After WWII, Britain faced a severe housing shortage. Traditional bricklaying was slow and labour-intensive, and there were material shortages. No-fines concrete offered a faster, cheaper way to build.

George Wimpey & Co. became one of the main contractors to adopt and refine no-fines concrete. By the late 1940s, Wimpey had secured contracts with local authorities (including Coventry City Council) to build thousands of homes using this system.

Wimpey standardised the construction process. They used reusable steel formwork to cast external walls on-site with no-fines concrete, allowing for quick turnaround times and consistent quality. This became known as the “Wimpey No-Fines” system.

Around 300,000 Wimpey No-Fines homes were built across the UK, many of which still exist today. In Coventry, large estates such as Canley and Tile Hill include Wimpey No-Fines houses, which remain a significant part of the city’s housing stock and architectural history.

No-fines concrete wasn’t invented by Wimpey but evolved gradually as a variation of conventional concrete. The concept of omitting fine aggregates (sand) and using only coarse aggregates, cement, and water has been documented since at least the early 20th century. Engineers and builders in Europe experimented with it during the 1910s–1930s as a way to reduce material costs and improve insulation.

In the UK, the method was first systematically applied on a large scale after World War II, when the Scottish Special Housing Association (SSHA) promoted it for fast, affordable housing. George Wimpey & Co. then refined and industrialised the system in England, creating the “Wimpey No-Fines” process.

The 1940s–1960s were the heyday of no-fines concrete in Britain. By the 1970s, brick supply had improved, construction skills were more available, and insulation standards were tightened. No-fines houses had poor thermal performance compared to emerging cavity-wall systems, and mortgage lenders began to see them as “non-traditional,” which limited sales.

After the 1980s the method was rarely used for new homes, but it continued occasionally in industrial or temporary applications where permeability and light weight were advantageous — for example, drainage layers, retaining walls, or specialist agricultural structures.

Today you will still see no-fines concrete specified for certain civil engineering works (like permeable sub-bases or lightweight fill) but almost never for mainstream UK housing. The main uses of no-fines concrete today are:

1. Permeable Base Layers and Drainage: Used under roads, pavements, car parks and sports fields because its open texture allows rapid drainage. Often called “no-fines sub-base” or “lean no-fines concrete” in civil engineering specs.

2. Retaining Walls and Backfill: Applied behind retaining walls to improve drainage and reduce hydrostatic pressure. Lightweight compared to standard concrete, so it reduces loads on structures.

3. Landscaping and Erosion Control: Used in embankments, slopes or coastal works to provide a permeable, stable fill that resists washout.

4. Void Formers or Fill for Irregular Spaces: Its flow and porosity make it useful to fill trenches, redundant culverts, or disused tunnels where future access isn’t needed.

5. Agricultural and Horticultural Uses: Occasionally specified in farmyards or greenhouses where drainage and low cost are priorities.

6. Specialist Building Components: Used in some precast blocks or lightweight elements where insulation and low density are desirable.

In short, no fines concrete has moved from a mainstream housing construction method to a niche, civil-engineering material.